GSI Grain Storage Bins & Tanks

Home - Equipment Sales - GSI Grain Storage Bins & Tanks

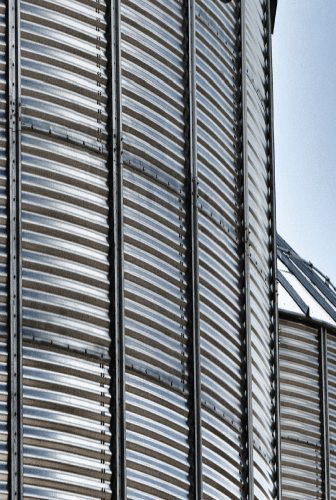

GSI Flat Bottom Bins

GSI grain bins are available in many sizes and configurations. Whether you need a small 1,000 bushel bin for a small farmer or a 1.9 million bushel bin for the commercial elevator, we have the commodity storage solution you need. GSI bins are customizable with many accessory options to better store and more efficiently move your grain.

Capture future carry in the grain market by storing your grain instead of selling at harvest. Increase your marketing flexibility and benefit from the ability to store grain so you can sell when the time is right.

- 4002 – Narrow corrugation unstiffened bin.

- 4004 – Wide corrugation unstiffened bin.

- 4024 – Wide corrugation stiffened bin.

- EVO50 – (Commercial) Wide corrugation stiffened bin with two or three stiffeners per sheet.

Stiffened vs Unstiffened Bins

Typically smaller diameter bins are most cost effective and unstiffened. Stiffened bins are not necessarily stronger structurally than unstiffened bins. Both have the same wind load rating at 105 MPH. The sheets on unstiffened bins are heavier gauge to compensate for missing stiffeners. However, unstiffened bins are not available or engineered for GSI grain bins over ten rings tall. Also, StirAtors can only be used on stiffened bins and stiffened bins may add more flexibility when using stiffeners as bracing for other structures

GSI Bin Accessories

GSI Stairs/Ladder System

Bin accessibility is important… Bins can be configured with a ladder (the most cost effective) or stairs. Inside ladders are standard. GSI bin roofs can be configured with rungs only, rungs with handrails, or stairs with handrails. Peak walk around options are also available. If two bins are placed side by side (recommended separation at four feet when sharing stairs), only one set of stairs is required along with a twin eave platform to enable access to the other bin.

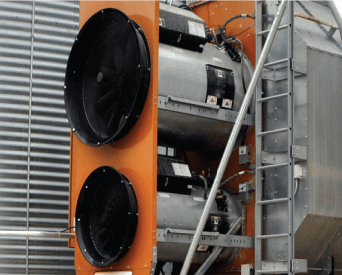

GSI Fans/Heaters

Grain must be conditioned and kept cool and dry to avoid grain loss. GSI offers many sizes of fans and fan heaters to help producers and processors to store their grain effectively. Axial fans are much louder but more economical but limited to 15HP. Centrifugal fans are more expensive, but are much quieter and can be sized up to 50HP. Propane or natural gas heaters can be mounted on both centrifugal and axial fans. More information can be found here.

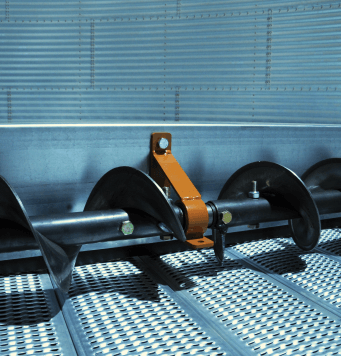

GSI Unloads/Sweeps

GSI has a variety of options when it comes to unload systems. DGD or direct gear drive sweeps are the most common. The unload tube and sweep are all driven by the motor on the outside of the bin. Different unload sizes 6”, 8”, 10”, and 12” are available depending on the size of the bin configured. Unloads can be configured as horizontal, incline (25 degree), or vertical. A vertical unload is a dual drive unload system that is used to load out trucks without requiring a field loader or an additional portable auger. Braker Grain Systems is also a dealer for DAAY paddle sweep systems. If you are looking for a better cleanout, this is the way to go. See more information on unloads and sweeps here.

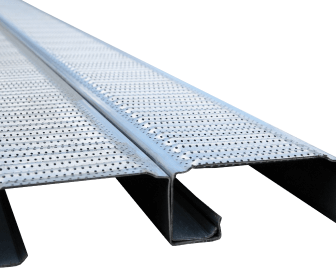

Floor Options

GSI offers three floor options: cor-lock, cut-lock, and dura-lock. The cor-lock and cut-lock systems use the formed grand stand supports where the dura-lock system uses a grid of monorails (similar to square tubing) to support the floor. Dura-lock floors are recommended for taller and larger bins as it is a sturdier option but it comes at a cost. For bins 10 rings and under with diameters 48 feet and under, cut-lock flooring is still a great choice and is a bit more economical.

Gravity Spreaders

GSI Hopper Tanks

Hopper tanks are ideal for feed applications, load out overhead tanks, or any storage tank that requires frequent cleanout. The basic hopper tank design allows for easy and complete cleanout. GSI hopper tanks are available in four product lines.

BFT: Bulk feed hopper tanks are typically used to store and protect feed small quantities. These are the smallest hopper tanks that GSI offers ranging from 6 feet – 15 feet in diameter.

GHT: These small capacity grain hopper tanks are best for handling free flowing grain. GHT tanks range from 9 feet – 21 feet in diameter and are commonly used for load-out tanks on overhead structures.

FCHT: These wide corrugation commercial hopper tanks are stiffened and offer larger capacity than the GHT series tanks. Ideal for a wet or dry bin where frequent load-out is required. Available from 18 feet – 24 feet in diameter with a standard 45 degree hopper.

NCHT: The biggest and strongest, these narrow corrugation commercial hopper tanks dwarf the others in terms of size and are typically used for commercial or speciality applications. Available from 12 feet – 36 feet in diameter with a 40, 45, or 60 degree hopper.

Daay Sweeps

Daay paddle sweeps are your solution for (nearly) complete cleanout. These sweeps use rubber paddles that (brush) the bin floor rather than the dangerous traditional sweep augers. More information here (include a link to Sioux Steel Daay Sweep website or brochure)

- Available in capacities up to 12,000 bushel per hour.

- Can be configured with a pivot kit to mount directly to a GSI DGD unload system that has been configured without the GSI sweep.

- These paddles sweeps clean the bin much more effectively than the traditional auger sweeps that leave several inches of grain on the bin floor that has to be manually swept into the unload.

- Manufactured by Sioux Steel Company.